Mastering the Art of Valves and Controls: A Beginner’s Guide

- by Jose Bryant

Welcome to the world of valves and controls, where precision and reliability are paramount in a wide range of industries. Whether you’re a newcomer or looking to deepen your knowledge in this field, understanding the functions and applications of valves and controls is essential. Valworx, an ISO 9001-certified supplier, stands out as a trusted provider of actuated valves and controls, offering an extensive selection of automated valve assemblies to meet the diverse needs of industrial, institutional, and government markets. With quick turnaround times and a commitment to quality, Valworx aims to simplify the process of acquiring and implementing these crucial components for your operations.

Types of Valves

One common type of valve is the ball valve, which utilizes a rotating ball to control the flow of liquids or gases. These valves are known for their reliability and versatility in various applications.

Economical butterfly valve for general service applications

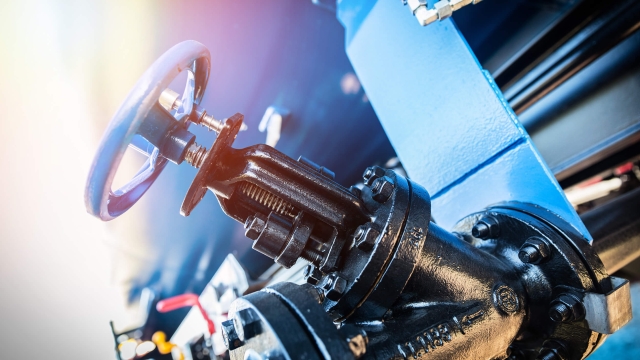

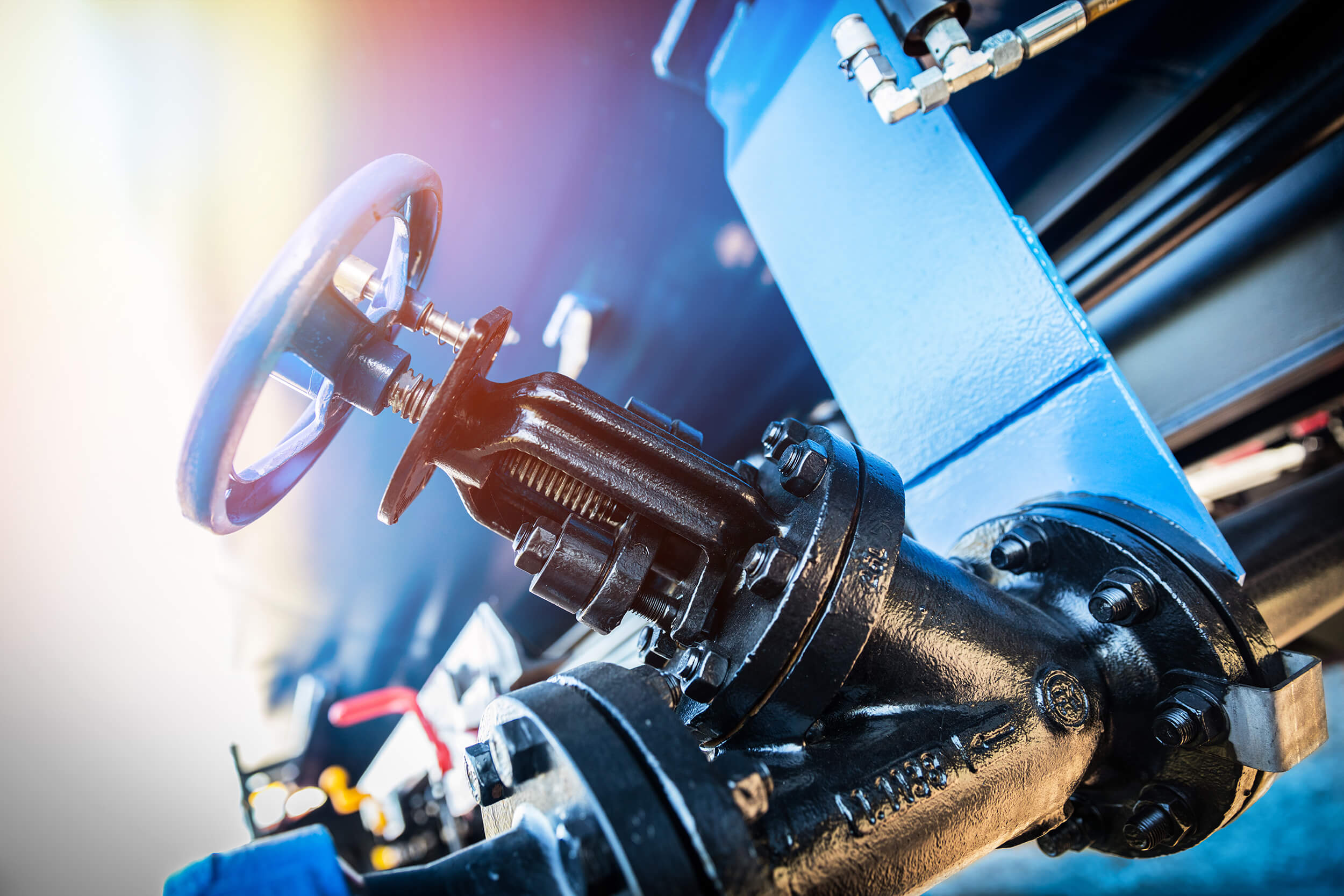

Gate valves are another type that is commonly used to start or stop the flow of fluid within pipelines. They operate by raising or lowering a gate within the valve body to control the flow.

Butterfly valves are also prevalent in industrial settings, where they control the flow by rotating a disc or vane within the pipeline. These valves are lightweight and require less structural support compared to other types.

Benefits of Actuated Valve Assemblies

Actuated valve assemblies offer a seamless integration of valves and controls, providing efficient and precise automated operation in various industries. This streamlined setup eliminates the need for manual adjustments, saving time and reducing the risk of human error in critical processes.

One of the key advantages of actuated valve assemblies is their ability to enhance system performance and reliability. By automating the valve operation, these assemblies ensure consistent and accurate control of flow rates and pressures, leading to improved process efficiency and product quality.

Furthermore, actuated valve assemblies contribute to enhanced safety measures by allowing remote monitoring and control of valve functions. This remote accessibility enables quick response to potential issues, minimizes downtime, and promotes a more secure working environment for personnel.

Applications in Different Sectors

In the oil and gas industry, valves and controls are integral components in the extraction, processing, and transportation of petroleum products. Valworx’s range of actuated valves play a crucial role in regulating the flow of various substances within pipelines and refinery equipment.

In the healthcare sector, precise control of fluids and gases is essential for the operation of medical devices and laboratory equipment. Valworx’s automated valve assemblies ensure reliable and accurate management of these substances, contributing to the efficiency and effectiveness of healthcare facilities.

Within the food and beverage industry, maintaining strict quality standards is paramount to ensure consumer safety. Valworx’s ISO 9001-certified actuated valves and controls are trusted for their consistency and reliability in regulating the flow and processing of food products, meeting the stringent requirements of this sector.

Welcome to the world of valves and controls, where precision and reliability are paramount in a wide range of industries. Whether you’re a newcomer or looking to deepen your knowledge in this field, understanding the functions and applications of valves and controls is essential. Valworx, an ISO 9001-certified supplier, stands out as a trusted provider…